- About Us

-

-

Company

- About Us

- Why Choose Us

- Contact Us

-

Insights

- Blog

-

-

- EV Solutions

- Solutions

-

-

- PRODUCTS

-

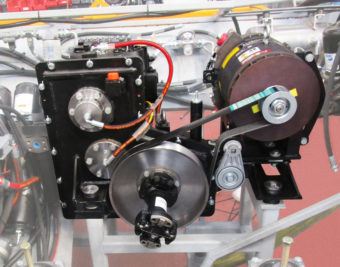

Driveline systems to meet every off-road need

- HEAVY DUTY VEHICLE MOBILITY

-

World-class expertise in heavy duty mobility

- ADVANCED ENGINEERING SERVICES

-

Expert and detailed engineering test, analysis & validation

-

- VEHICLE UPGRADE SERVICES

-

Upgrade your vehicle and extend life with our expert assessment services

- TECHNOLOGY TRANSFER & LICENSING

-

Flexible business models

- AFTERMARKET

-

-

- Defence

-

-

Defence

Timoney has been trusted by

leading defence OEMs for over 50

years

-

- Products

-

Driveline systems to meet every off-road need

- HEAVY DUTY VEHICLE MOBILITY

-

World-class expertise in heavy duty mobility

- RIDE & HANDLING SERVICES

-

Ride & Handling Issues…SOLVED

- VEHICLE UPGRADE SERVICES

-

Upgrade your vehicle and extend life with our expert assessment services

-

- TECHNOLOGY TRANSFER & LICENSING

-

Flexible business models

- AFTERMARKET

-

Spares and support when you need it

- Case studies

-

Practical examples of how we help our customers

-

-

- Construction

-

-

Construction

We work with global OEMs who need best in class operator comfort

-

- PRODUCTS

-

Driveline systems to meet every off-road need

- HEAVY DUTY VEHICLE MOBILITY

-

World-class expertise in heavy duty mobility

- RIDE & HANDLING SERVICES

-

Ride & Handling Issues…SOLVED

-

- TECHNOLOGY TRANSFER & LICENSING

-

Flexible business models

- AFTERMARKET

-

Spares and support when you need it

- Case studies

-

Practical examples of how we help our customers

-

-

- Fire

-

-

Fire

Improve emergency response times

with best in class ride and handling

-

- PRODUCTS

-

Driveline systems to meet every off-road need

- HEAVY DUTY VEHICLE MOBILITY

-

World-class expertise in heavy duty mobility

- RIDE & HANDLING SERVICES

-

Ride & Handling Issues…SOLVED

- VEHICLE UPGRADE SERVICES

-

Upgrade your vehicle and extend life with our expert assessment services

-

- TECHNOLOGY TRANSFER & LICENSING

-

Flexible business models

- AFTERMARKET

-

Spares and support when you need it

- Case studies

-

Practical examples of how we help our customers

-

-